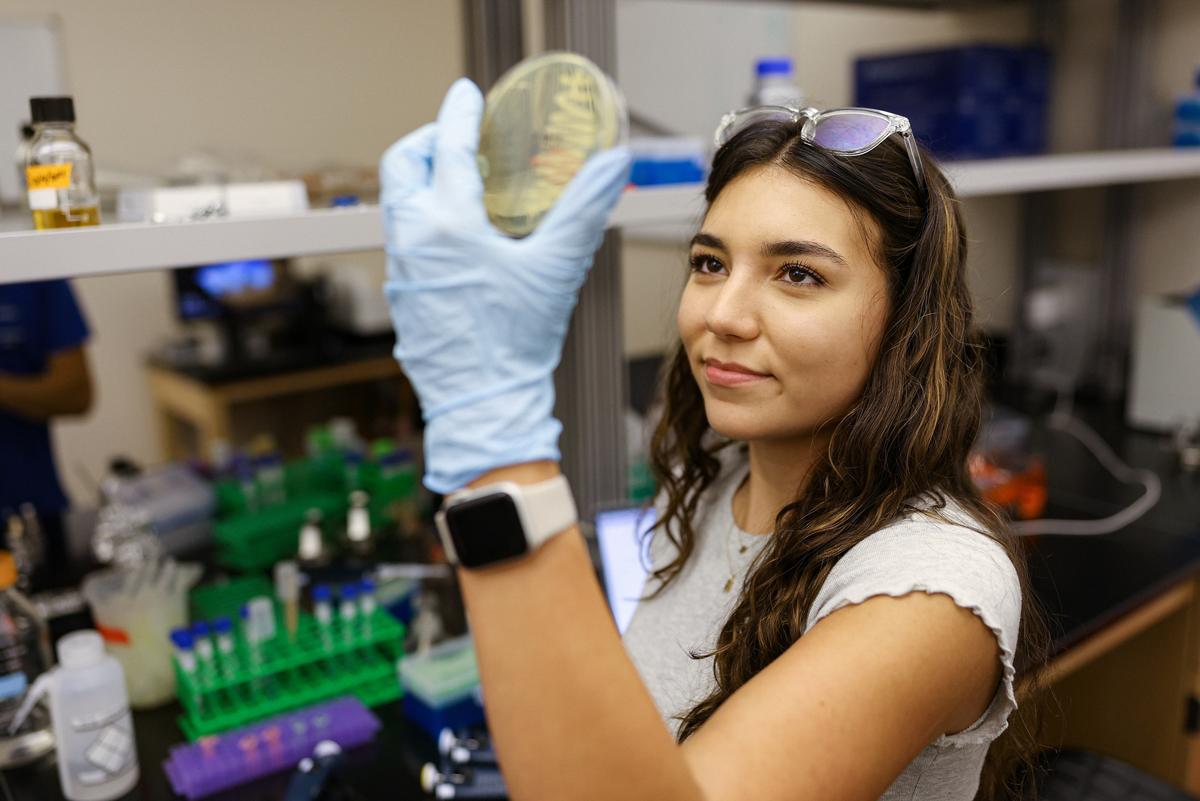

It’s hard to see much potential in the 55 gallon tank of waste vegetable oil (WVO) currently sitting in a small green shed past the South Housing parking lot. A small group of Furman students, however, are making use of what others would discard, transforming the used vegetable oil into biodiesel that they can sell to Facilities Services and local vendors.

“[Biodiesel is] waste that is given a second purpose,” said Elisabeth Schlaudt, who is heading the biodiesel initiative.

The project initially began at Furman six years ago. Facilities Services helped install the necessary equipment and supplied the project with materials and funds. Students lost interest in the program after two years though, unable to commit the time necessary to make the project successful.

Now, four years later, Schlaudt has used trial and error to regain lost knowledge.

“I want to close the loop; instead of consuming, creating,” said Schlaudt

Schlaudt said she has had to experiment with biodiesel because the instructions left behind from when the project first started were incorrect or did not apply to the current equipment.

The WVO is collected from the Dining Hall and the Paladen. Methoxide is the key ingredient in biodiesel and the amount needed must be found by doing an experimental process called titration.

The WVO and methoxide are mixed together and heated to 130 degrees Fahrenheit. This is dangerous because the methoxide becomes combustible at 140 degrees Fahrenheit and could catch on fire or explode.

The biodiesel must be rinsed with a fine mist of water and allowed to sit for two to five days. The entire process takes less than two weeks.

The byproduct of the biodiesel reaction is glycerin which can be used to make soap. Schlaudtcurrently has no plans to make soap but said that if there is more interest in the project then soap could be a project for the winter when the hot water tanks and pipes get too cold to make biodiesel.

Biodiesel is not practical on a large scale, but is useful to reduce a personal impact, said Schlaudt.

“[Making biodiesel] is a great community builder because it is a very local project,” said Schlaudt.

The biodiesel will be sold back to Facilities Services for use in their lawnmowers and othergroundskeeping machinery. B-20 biodiesel—20% biodiesel and 80% regular diesel—is what they are making.

“I want to make a physical difference, and if given the financial resources, I want to convert a school bus to biodiesel and help promote the Furman Farm by selling their produce to the community and holding educational programs at local elementary schools,” said Schlaudt.

If at least four students are willing to learn the entire biodiesel process, educational workshops could become a possibility. Work study approval is in process for students willing to work a couple of hours a week.

“The only way to make this work is for students to have an incentive to work,” said Schlaudt

The work study opportunity and the idea of possibly making his own fuel drew freshman Michael Baldwin to the biodiesel project.

“I had been learning about large scale foreign biodiesel in my economics class,” said Baldwin.

He is currently helping out where he can and learning the basics of biodiesel.